What Are the Different Types of Wires in Robotics?

Jan 22, 2025

Robots are complex systems that rely on various types of electronic wires to ensure efficient power distribution, signal transmission, and communication between components. The selection of appropriate wires plays a crucial role in the performance, durability, and flexibility of robotic systems. Depending on the function, different types of wires are used in robots, including power cables, signal wires, data transmission cables, and high-flex cables.

Types of Wires Used in Robotics

Power Cables

Power cables are responsible for transmitting electrical energy from the power supply to the motors, actuators, and control units of a robot. These wires need to have high current-carrying capacity, low resistance, and strong insulation to prevent energy loss and overheating.

Common specifications: UL20276 wire, AWM 20276 wire

Applications: Industrial robots, autonomous vehicles, robotic arms

Signal Wires

Signal wires transmit low-power electrical signals between different components of the robotic system, such as sensors, microcontrollers, and motor controllers. These wires must be shielded to reduce electromagnetic interference (EMI), ensuring accurate data transfer.

Common specifications: Shielded twisted pair (STP), coaxial cables

Applications: Robotic sensors, automation systems, medical robotics

Data Transmission Cables

Modern robots rely on high-speed data transmission for real-time communication and processing. Wires such as Ethernet cables, USB cables, and fiber optic cables enable fast and stable data exchange between robotic components and external systems.

Common specifications: Cat6 Ethernet cables, USB 3.0 cables, fiber optics

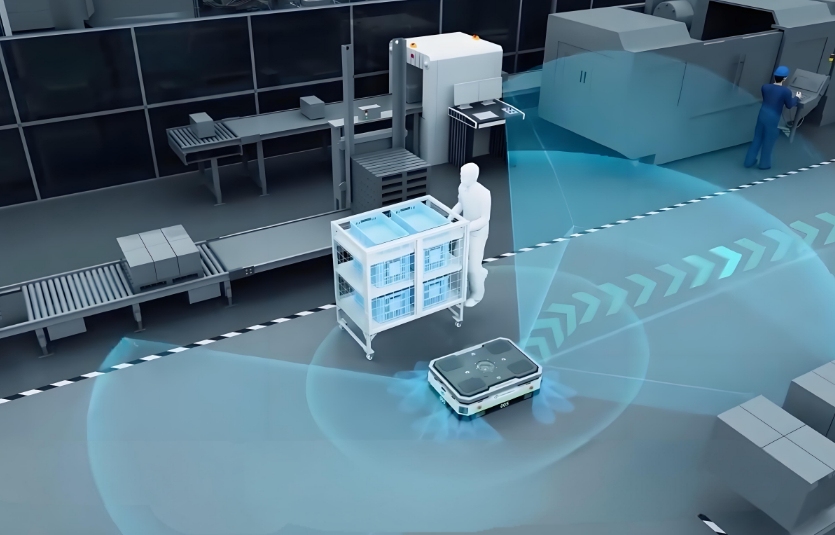

Applications: AI-driven robots, autonomous systems, industrial automation

High-Flex Cables

Robots require flexible cables that can withstand constant bending, twisting, and movement without breaking. High-flex cables are designed to endure mechanical stress and have a longer lifespan compared to standard wires.

Common specifications: Teflon-coated wires, silicone-insulated cables

Applications: Robotic arms, automated machinery, wearable robotics

Electronic Wire Processing Industry Helps Production Robots

Under the general trend of intelligent manufacturing, the electronic wire processing industry plays a crucial role in improving the production of robots. While it primarily focuses on cable production, it also brings significant advancements to the manufacturing and assembly processes of robotic components.

Providing Reference for Precision Manufacturing Processes

High-Precision Processing Technology Adaptation

Electronic wire processing often involves cutting, stripping, welding, and assembling extremely fine wires with micron-level accuracy. For example, in the production of microelectronic device wires, cutting errors must be controlled within minimal tolerances to maintain electrical performance and mechanical reliability. This level of precision is essential for manufacturing critical robotic components such as joints, sensors, and circuit boards.

By adopting high-precision control methods used in electronic wire processing—such as computer numerical control (CNC) machining and precision mold manufacturing—robot manufacturers can significantly improve the quality of precision parts. This leads to lower defect rates, smoother robotic movements, and improved positioning accuracy.

Expansion of Micro-Nano Manufacturing Technology

As robotics and electronic devices become increasingly miniaturized, the electronic wire processing industry is continuously exploring micro-nano manufacturing techniques. Methods like photolithography and etching enable the production of ultra-thin, high-performance electronic wires with specialized surface structures. These innovations contribute to the development of compact, lightweight, and highly efficient robots, enhancing their adaptability in fields such as medical robotics, aerospace, and advanced automation.

Importance of Wire Selection in Robotics

Selecting the right wires for robotic applications is essential for ensuring safety, efficiency, and longevity. Key factors to consider include:

Voltage and Current Capacity: Ensuring wires can handle the required electrical load without overheating.

Flexibility and Durability: Choosing high-flex cables for moving parts to prevent wire fatigue and breakage.

Shielding and EMI Protection: Using shielded cables for signal and data transmission to reduce interference.

Temperature and Environmental Resistance: Selecting heat-resistant and chemical-resistant insulation materials for harsh environments.

Future Trends in Robotic Wiring

With advancements in artificial intelligence (AI), machine learning, and automation, the demand for more sophisticated and efficient wiring solutions is increasing. Future trends in robotic wiring include:

Smart Wires with Built-in Sensors: Wires capable of self-diagnosing faults and transmitting real-time data for predictive maintenance.

Wireless Power Transmission: Reducing dependency on traditional wiring by using inductive charging and energy harvesting technologies.

Biodegradable and Eco-Friendly Insulation Materials: Developing sustainable wiring solutions to reduce environmental impact.

Miniaturization and Lightweight Wires: Improving energy efficiency and enhancing the mobility of robotic systems.

The role of electronic wire processing in robotics goes beyond cable production—it influences precision manufacturing, high-performance connectivity, and technological advancements in robotic design. By integrating high-precision processing techniques, micro-nano manufacturing, and advanced wiring solutions, the robotics industry can continue to innovate and push the boundaries of intelligent automation.

Network Supported

Network Supported