How Many Wiring Harnesses Are in a Vehicle?

May 06, 2025

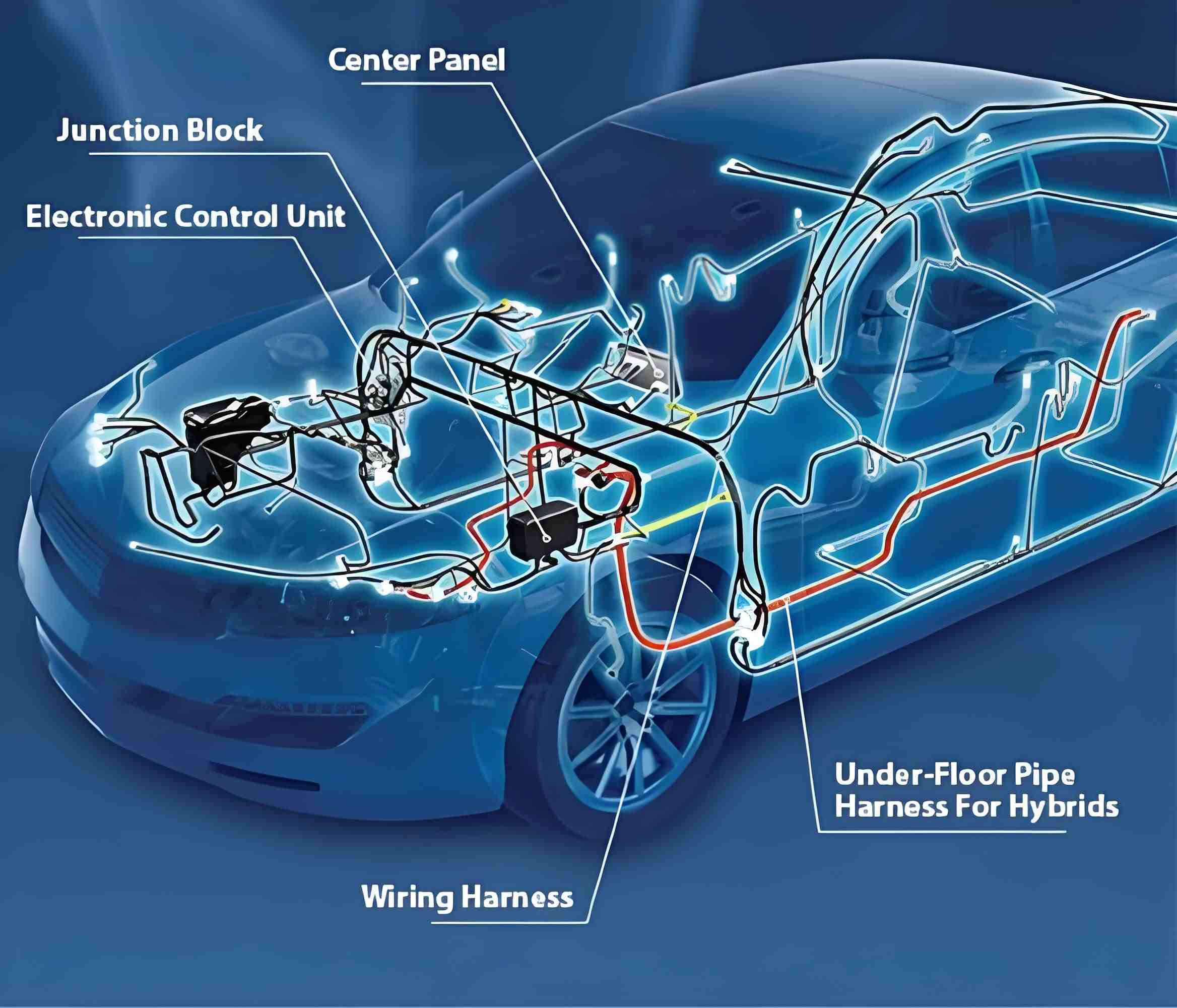

Modern vehicles are complex electromechanical systems that rely heavily on intricate wiring structures to function efficiently. Among the most critical components in automotive electrical architecture is the wiring harness, which serves as the central nervous system for distributing electrical power and signals to all electronic modules and devices.

Understanding the Structure of Automotive Wiring Harnesses

A standard passenger vehicle typically contains 15 to 30 individual wiring harnesses, depending on the level of technological integration, model class, and configuration. These harnesses are strategically grouped based on vehicle zones and functional systems—such as engine, chassis, dashboard, infotainment, lighting, and powertrain. In high-end vehicles with advanced driver-assistance systems (ADAS), the total number may exceed 50.

Each wiring harness comprises dozens to hundreds of wires, bundled together using insulation tapes, corrugated tubes, or protective sheaths. They connect sensors, control units, switches, and actuators, ensuring that electrical signals travel reliably throughout the vehicle.

Major Types of Automotive Wiring Harnesses

One of the most critical types is the engine wiring harness, which connects components like ignition coils, fuel injectors, temperature sensors, and the engine control unit (ECU). Due to the high thermal and mechanical stress in the engine bay, this harness requires heat-resistant and vibration-damping materials.

Another essential category is the dashboard wiring harness, responsible for linking the instrument cluster, infotainment system, air conditioning controls, and steering wheel switches. This harness often requires precision routing and flexible layouts to accommodate design constraints and ergonomic requirements.

Modern vehicles also employ a chassis wiring harness, which integrates systems such as anti-lock braking (ABS), traction control, and suspension controls. It typically runs along the underbody and must be protected against moisture, debris, and abrasion.

Wiring Harness Complexity and Vehicle Design

The complexity of vehicle electronics has significantly increased with the integration of CAN bus systems and distributed electronic control units (ECUs). Each subsystem often requires dedicated communication pathways, which must be accounted for in the wiring harness design. Therefore, engineers utilize advanced CAD software and simulation tools to develop custom automotive wire harness assemblies tailored to each vehicle model.

The overall weight of the wiring harness system can exceed 60 kilograms in luxury cars, making lightweight materials and efficient routing strategies a growing focus in the industry. Additionally, as vehicles become more modular, manufacturers are beginning to adopt modular harness platforms, which allow easier assembly and future upgradability.

A modern vehicle contains multiple wiring harnesses—ranging from 15 in basic models to over 50 in technologically advanced ones. Each plays a specialized role in ensuring the seamless operation of electrical systems. From the engine wiring harness to the dashboard harness and beyond, these components are engineered with precision, contributing to the safety, functionality, and comfort of the vehicle. As automotive innovation continues, wiring harnesses will evolve in design and material, playing an even more central role in next-generation mobility.

Network Supported

Network Supported