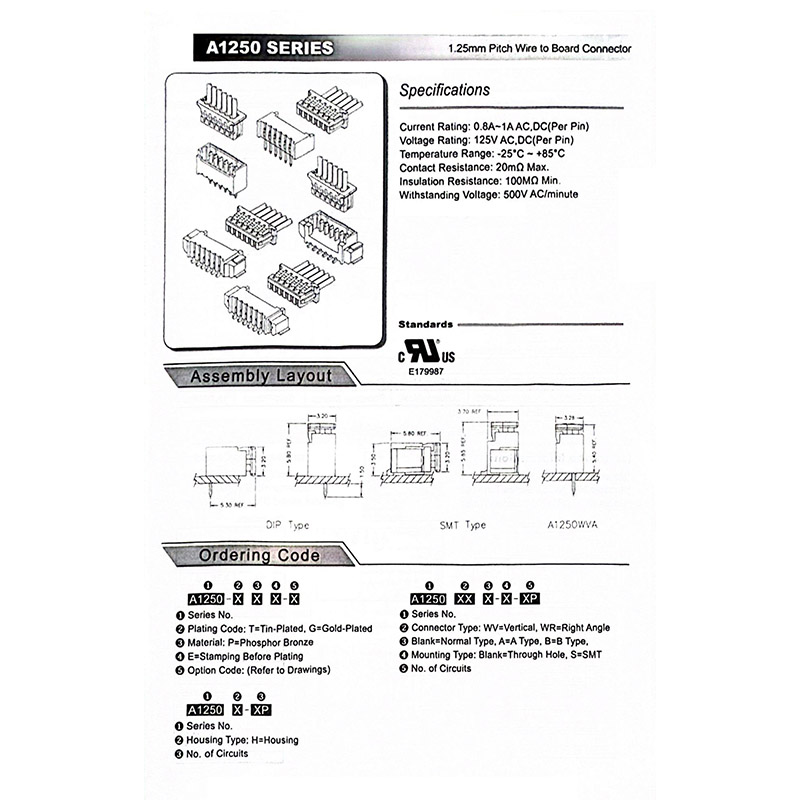

A1250 Durable Wire-to-Board Connectors

I. Product Advantages

(1) Environmental Compliance

The product uses environmentally friendly materials that meet ROHS and UL standards. After strict testing, it is safe and reliable throughout its life cycle. There is no pollution during production and use, and no potential health hazards, allowing you to use it with confidence.

(2) Flexible Customization

- Wire Gauge: The standard 28 - 32AWG wire gauge can meet regular requirements, and special specifications can also be customized to adapt to different current transmission needs or special material and structure requirements.

- Connector Housing: The standard A1250 connector housing is stable in performance. If the project has special requirements for interface shape, size, or protection, other types of connector housings can also be customized.

- Dimensions: With advanced equipment and technology, the dimensions are accurately customized according to customer requirements, ensuring a perfect fit during product installation and use.

(3) Precision Process

- Machine Wire Stripping: Automated wire stripping technology is used to accurately control the stripping length and force, avoiding damage to the wire. It has high efficiency and stable quality, laying a foundation for subsequent processes.

- Terminal Crimping: The cold crimping terminal process is adopted. With the help of professional equipment, the terminals and wires are tightly connected, reducing the contact resistance and ensuring stable current transmission. The connected parts can withstand high tensile and vibration forces.

- Manual Connector Housing Installation: Automation is used for wire stripping and terminal crimping, while the installation of the connector housing is carried out by experienced workers to ensure proper installation and handle minor assembly issues, guaranteeing the overall product quality.

II. Product Details

The product is produced by a professional manufacturer with OEM/ODM capabilities and supports customization of product colors and designs.

(1) Basic Product Specifications

- Wire Gauge: The standard 28 - 32AWG is suitable for internal connections of common electronic devices, and special specifications can also be customized.

- Connector Housing: The standard A1250 connector housing has good electrical and mechanical properties, and other types can also be customized as needed.

- Dimensions: Accurately produced according to strict customer requirements, suitable for large and small - sized equipment.

- Applications: Used for internal connections of displays, cameras, sensors, and industrial equipment, ensuring stable transmission of signals and data.

(2) Materials and Processes

- Wire: High - purity oxygen - free copper conductors are used, with low resistance, high transmission efficiency, good flexibility and oxidation resistance, extending the service life.

-

- Connector Housing: High - temperature - resistant materials with UL94V - 0 flame retardant certification are selected. The performance is stable at high temperatures, and it can effectively prevent fire.

- Automated Production: A large number of automated devices are used, and each production link is strictly controlled to ensure consistent product quality.

-

- Cold Crimping Terminals: A key process that tightly connects terminals and wires, preventing loosening and oxidation, and enabling stable signal transmission even in harsh environments.

-

- Manual Full Inspection: After assembly, technicians conduct a full inspection of the product's appearance, dimensions, and connection performance to ensure product compliance.

(3) Service Guarantee

- Delivery Time: Determined through negotiation according to the complexity of customization. With efficient production management and an experienced supply chain, the cycle can be shortened, and there is an emergency mechanism for urgent orders.

- Standard Packaging: Bundling straps, EPE foam, and cartons are used for packaging to prevent scattering, provide cushioning, and protect the product. Custom Packaging: Packaging dimensions can be customized as required, and brand logos can be printed.

- Transportation Method: Cooperate with well - known express delivery companies and freight forwarders. Both sea and air transportation are available, providing door - to - door services.

- Minimum Order Quantity: Determined through negotiation, small - batch trial production is supported to reduce costs and risks in the initial stage of the project.

III. Application Scenarios

(1) Internal Connections in Consumer Electronics

In products such as smartphones, tablets, and laptops, it connects various components, meeting the miniaturization and high - performance requirements of products, and ensuring the normal operation of the device and the rapid transmission of data.

(2) Signal Transmission in Industrial Control Equipment

Applied to industrial automation equipment and control systems, such as connections of PLCs, inverters, and sensors. High - purity oxygen - free copper conductors and precision processes can resist electromagnetic interference, ensuring accurate and stable signal transmission.

(3) Sensor Wiring Harnesses in Smart Homes

Connects various sensors such as temperature, humidity, and human infrared sensors, accurately transmitting data to the smart home control system. High - temperature - resistant, flame - retardant connector housings and stable connection performance can adapt to complex environments.

(4) Wiring Harnesses in Vehicle - mounted Electronic Systems

Used for connections of vehicle - mounted electronic devices such as instrument panels and vehicle - mounted displays. Good electrical and mechanical properties and high and low - temperature resistance can adapt to different road conditions and climates, ensuring the normal operation of vehicle - mounted electronic systems.

Network Supported

Network Supported